Description

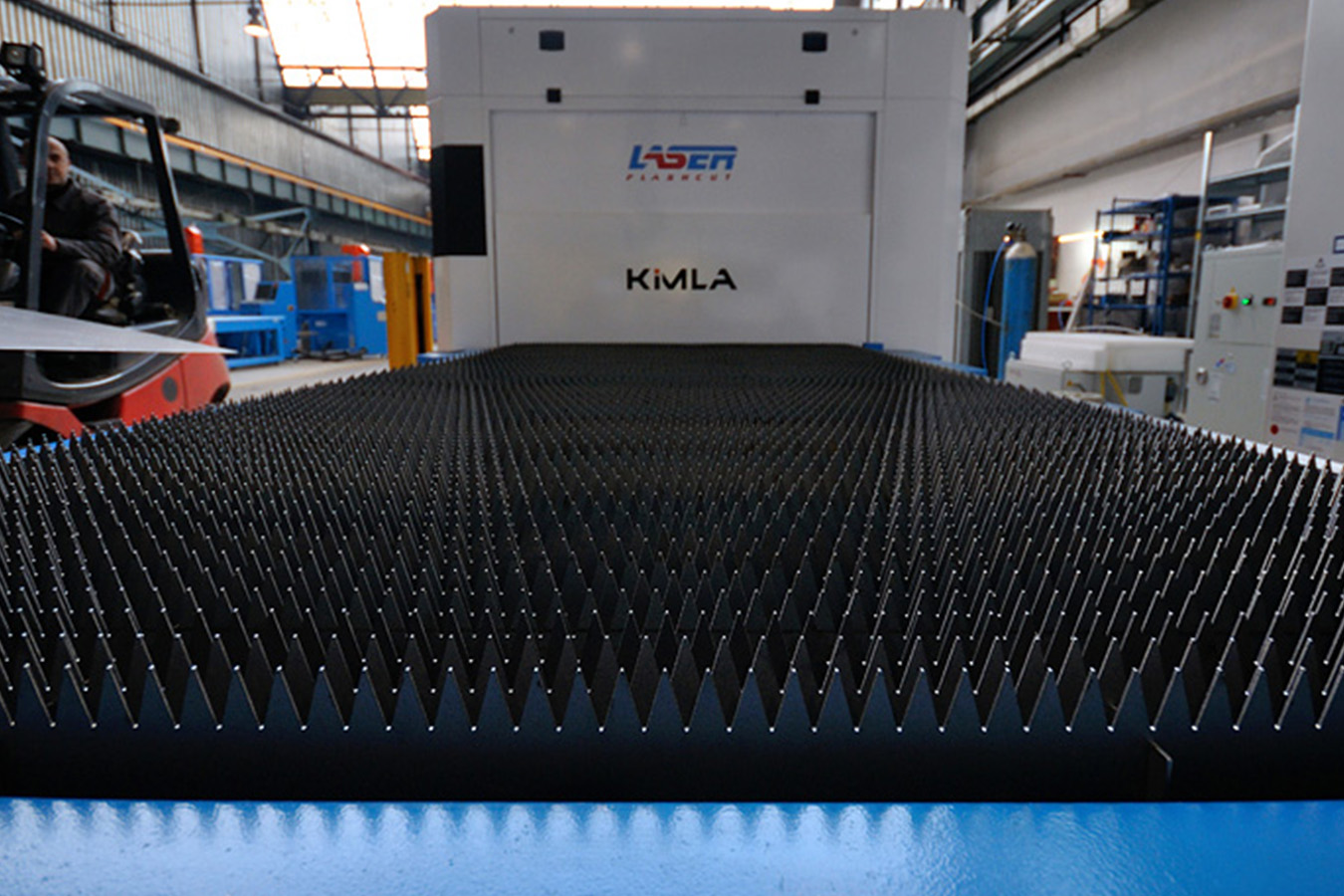

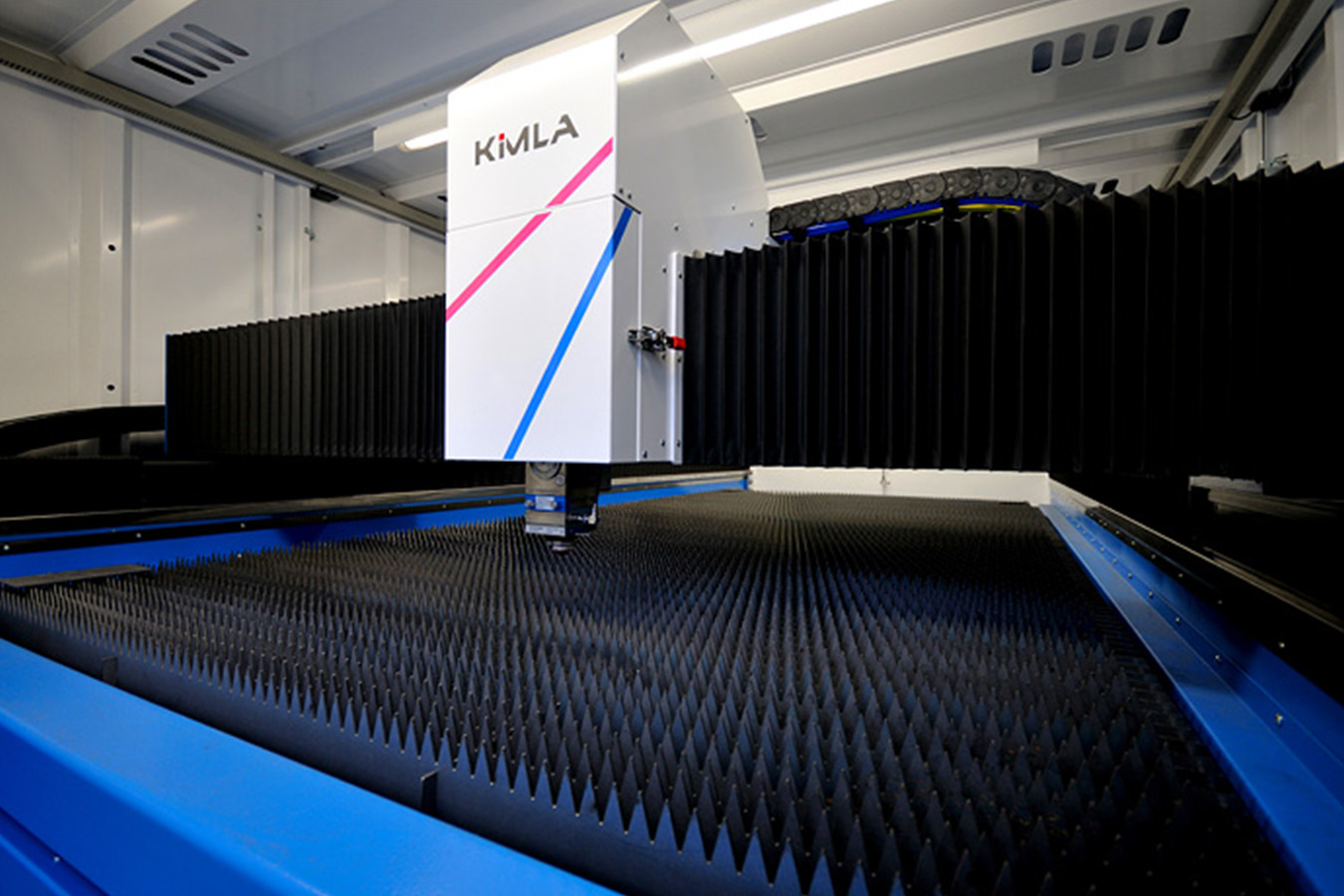

Fiber Laser with linear drives, facilitating fast and efficient cutting of various shapes out of sheet metals is the newest product designed by Kimla – the leading manufacturer of CNC machines.

The difference in operation of Kimla lasers and CO2 lasers is especially visible in the case of thin sheet metals, up to 5mm of thickness. The cost of metal cutting with the use of Fiber Linear laser may be drastically reduced, thanks to much higher power efficiency, reaching 30% (in CO2 lasers – merely up to 5%) and greater energy concetration, stemming from the shorter wavelenght.

The Kimla fibre lasers feature many advantages: superb quality, high efficiency, competitve price and the possibility of customization to individual customer’s needs.

The Kimla lasers are manufactured in many configurations and in operating areas.

The diversification pertains to: the degree of automation, laser source power and equipment. Kimla manufactures lasers with one worktable, in which an important factor is a low price for high performance; as well as production lasers with automatic pallet change and featuring ventilating hood systems, nesting and production preparation systems.

The Kimla lasers are machines featuring the highest efficiency, maximum speed and acceleration. Thanks to unique functionalities of very fast cutting of thin sheet metals, they are perfect for cutting out as an alternative to lathe punching-presses. The later ones were – up to now – considered the cheapest technology for cutting sheet metal details.

Flashcut and Powercut Linear lasers have won many gold medals at the Poznań International Fair (Międzynarodowe Targi Poznańskie – MTP; the largest trade fairs of modern industrial technologies – ITM Polska MACH-TOOL) and STOM trade fairs in Kielce.